Application Overview

★ Under vacuum, the boiling point of the material solution decreases, which increases the heat transfer driving force of the evaporator. Therefore, a certain amount of heat transfer can save the heat transfer area of the evaporator.

★ The heat source for evaporation operation can be low-pressure steam or waste heat steam (water or oil heating can be selected according to special user requirements, and the factory can design it specifically for you).

★ Suitable for drying heat-sensitive materials that are prone to decomposition, polymerization, and deterioration at high temperatures.

★ Before drying, disinfection treatment can be carried out, and no impurities are mixed during the drying process.

★ Due to its static vacuum dryer, the shape of the dried material will not be damaged.

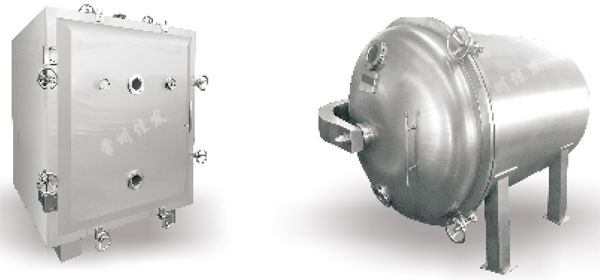

Project specifications | YZG-600 | YZG-1000 | YZG-1400 | FZG-15 |

Drying box size(mm) | Ø600×976 | Ø1000×1527 | Ø1400×2054 | 1500×1400×1220 |

External dimensions of the drying oven(mm) | 1135×810×1020 | 1693×1190×1500 | 2386×1675×1920 | 1513×1924×2060 |

Number of layers of drying rack | 4 | 6 | 8 | 8 |

Interlayer distance(mm) | 81 | 102 | 102 | 122 |

Oven size(mm) | 310×600×45 | 460×640×45 | 460×640×45 | 460×640×45 |

Number of baking plates | 4 | 12 | 32 | 32 |

Pressure inside the baking tray tube | ≤0.784(8kg/cm²) | ≤0.784 | ≤0.784 | ≤0.784 |

Operating temperature of drying rack(℃) | 35-150 | 35-150 | 35-150 | 35-150 |

Empty vacuum inside the box(Mpa) | ≤0.098(1kg/cm²) | ≤0.098 | ≤0.098 | ≤0.098 |

When using a condenser, the vacuum pump model | 2×-15A 2Kw | 2×-30A 3Kw | 2×-70A 5.5Kw | 2×-70A 7Kw |

When not using a condenser, the vacuum pump model | SK-0.8 2.2Kw | SK-3 5.5Kw | SK-3 5.5Kw | SK-3 5.5Kw |

Drying oven weight(Kg) | 250 | 800 | 1400 | 2100 |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.