Summary

★ This machine adopts a large area sandwich heating method, with a large heat transfer surface and high thermal efficiency.

★ This machine is equipped with stirring to form a continuous circulation of materials in the barrel, further improving the uniformity of material heating.

★ This machine is equipped with stirring to smoothly dry slurry, paste, and paste materials.

Principle

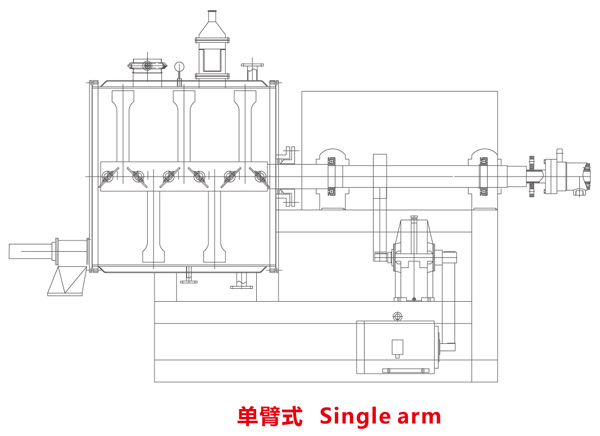

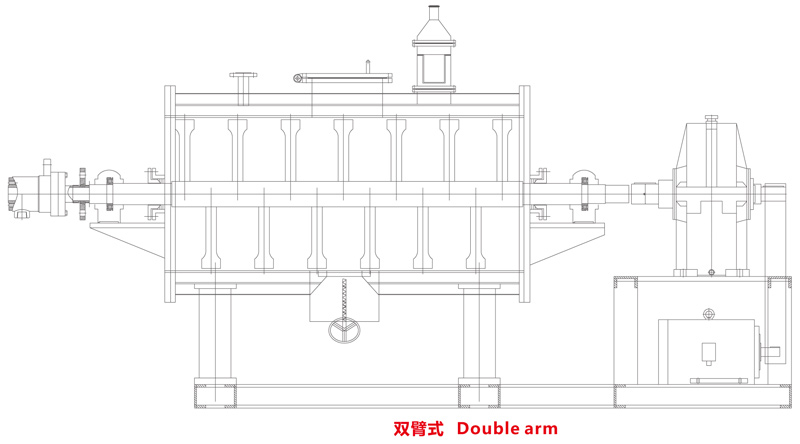

This machine is a new type of horizontal intermittent vacuum drying equipment. Wet materials are evaporated through conduction, and a scraper mixer is equipped to continuously remove the materials on the hot surface. The material is then pushed inside the container to form a circulating flow. After the water evaporates, it is pumped out by a vacuum pump.

Application

★ Drying of the following materials in pharmaceutical, food, chemical and other industries

★ Suitable for paste, paste, and powder materials.

★ Heat sensitive materials that require low-temperature drying.

★ Easy to oxidize, explosive, highly irritating, and highly toxic materials.

★ Require the recovery of organic solvent materials.

Model | ZPG-500 | ZPG-750 | ZPG-1000 | ZPG-1500 | ZPG-2000 | ZPG-3000 | ZPG-5000 | |

Working volume | L | 300 | 450 | 600 | 900 | 1200 | 1800 | 5000 |

Inner cylinder size | mm | Ø600×1500 | Ø800×1500 | Ø800×2000 | Ø1000×2000 | Ø1000×2600 | Ø1200×2600 | Ø1400×3400 |

Stirring speed | rpm | 6~30 stepless speed regulation | ||||||

Power | Kw | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 22 |

Design pressure of interlayer | MPa | ≤0.3 | ||||||

Pressure inside the cylinder | MPa | -0.096~0.15 | ||||||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.